Food safety

Ten Ren has adopted the highest inspection standards on the quality of tea which are inspected by batches, and all products must pass inspection before shipment. However, under such strict standards, there was still an oversight. On May 4, 2015, black tea sold to Easy Way was found to contain excessive amounts of pesticide, Fipronil, with over 0.001ppm. Ten Ren is fully responsible for this incident. In addition to releasing a statement immediately to notify the public, Ten Ren was also committed to stricter quality inspections in the future with regard to food safety, and will randomly inspect bar food daily, including ice cubes used at the bars, in Ten Ren's food safety lab. Meanwhile, Ten Ren will commission a third party inspection unit such as SGS, to conduct spot checks on raw tea materials and tea products in the stores. Ten Ren will truthfully publish the outcome on the SGS information platform.

SGS information platform - Ten Ren Tea section http://twap.sgs.com/sgsrip/comview.asp?cstno=18559415

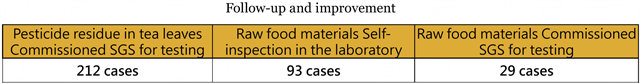

In May of 2015, the inspection of pesticide residues on tea leaves (including raw materials and products) appointed to SGS totaled 212 cases, while the inspection on raw food materials (including food materials, ice cubes, drinking water, and products) carried out internally by Ten Ren's own food safety laboratory totaled 93 cases, and inspections on raw food materials (including ingredients and beverages) appointed to SGS totaled 29 cases.

In addition to maintaining batch inspection on all raw materials, Ten Ren has appointed SGS to carry out spot checks on raw materials and tea products at the bars in all stores and distribution channels throughout Taiwan. Ten Ren wishes to create a more reassuring environment for consumers through double checking to monitor food safety. Ten Ren has also cooperated with SGS information platform, where relevant inspection reports are made available on the platform at any time.

Batch inspection

Ten Ren has adopted the highest standard to ensure our food safety. For Ten Ren, samples taken from every batch of dry tea leaves are sent to SGS for testing before it is accepted in the storehouse, and each batch of dry tea leaves can only be accepted if the samples have passed. There are 300 to 400 kinds of pesticides that "may be detected" and "may be used" in Taiwan. Ten Ren spends over NT$3 million on testing every year. The general sampling check in the market requires companies to set a certain percentage for sampling check, such as 1,000 batches per year, or set a certain sampling percentage for a certain type of tea; it can be conducted before or after acceptance, there is no well established standard. Therefore, the batch testing method adopted by Ten Ren for many years is the highest testing standard in the industry. The batch testing of dry tea leaves conducted by SGS totaled 679 in 2014. Regarding product labeling, product information is 100% disclosed in accordance with regulations. There was no violation of food safety and health management regulations in 2014.

Setup a food safety laboratory

●The establishment of the laboratory:2015/4/10

●The purpose of the lab: Food safety and assurance/ happiness from tea

●Planning for laboratory by phase: conduct sanitary inspections on the appliances used during the food production process, and conduct microbial detection on ice cubes, drinking water, and prepared foods using quick test kits

●Main work items: ATP detection, total microbial count/E. coli/E. coli culture, quick screening of medication use for meat animals/antibiotic residue in meat products, and quick screening of pesticide residue in fruits and vegetables.

●Names and purposes of equipment in the laboratory, names or categories of raw materials or products applicable to self-testing